Wednesday, 9 November 2011

Friday, 4 November 2011

Monday, 10 October 2011

Monday, 12 September 2011

Saturday, 27 August 2011

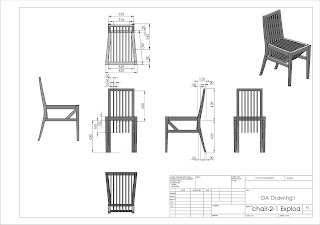

Statement_Purchased Chair

The chair includes two parts: frame and cushion. The main material of chair frame is timber, they are joint each other by nails, screws and staples.

Back frame, vertically, and back leg are made in one piece of timber, within an ergonomic shape. In the same shape, there are 6 long timber pieces, which are thinner than the frames, installed at the back part, to make comfortable for people sitting on. These 6 pieces are joint to back frame, horizontally, by nails and glue.

The seat frame is made of 4 pieces of timber sticks, constructed in a square shape. They are connected with front legs and back part by nails, staples and glue. At corners of the square frame, 4 wooden triangle blocks support the seat frame more stable, they are joint by nails and 2 crews on each blocks.

Between front and back legs, 2 pieces of timber sticks hold them tightly.

For the cushion part, a seat shape timber board is at bottom, the surface of the seat is made from artificial leather, a piece of sponge is sandwiched between timber board and leather. The artificial leather covers sponge and timber board, it is stapled on the underside of the timber board neatly. The cushion connects with frame by 3 pieces of brace and screws.

For the finishing, veneers are glued on each surface of timber, to make them smooth.

To hide the raw material, where in the underside of the seat part, there is a piece of black nylon fabric covering the underside space, which is stapled on the seat frame.

Tuesday, 16 August 2011

Monday, 15 August 2011

Contextual Essay

Charles EAMES (designer)

United States 1907- 78

United States 1907- 78

LCW chair (LCW = Lounge Chair Wood)

1945 designed, 1940s manufactured

plywood, rubber

1945 designed, 1940s manufactured

plywood, rubber

Charles Eames designed some of the most important examples of 20th century furniture, he also applied his talents to devising ingenious children's toys, puzzles, films, exhibitions and such iconic mid-20th century Los Angeles buildings as the Eames House and Entenza House in Pacific Palisades. He developed a successful technique for moulding plywood into three-dimensional shapes, which led to the creation of a variety of furnishing and sculptures. Charles' design is a successful synthesis of formal and technical innovation.

The materials of LCW chair are moulded ash plywood; the seat and backrest sections connected to the base by means of rubber/metal elements (shock mounts). In the early 1940s, Charles Eames used thin sheets of veneer and a bicycle-pump compressor, experimenting with wood-molding techniques. In order to produce the Plywood Group layers of plywood are bent, pressed into shape and then hardened. The gently curving surfaces of the thin wooden back and seat shells give support to the body. Individual elements are fixed to the frame by means of supple rubber discs, which increase sitting comfort.

For more than four decades, American designer Charles Eames helped shape nearly every facet of American life. From his architecture, furniture, and textile designs to his photography and corporate design, he exerted a profound influence on the visual character of daily life in America, whether at work or at home. He pioneering use of new materials and technologies, notably plywood and plastics, transformed the way Americans furnished their homes, introducing functional, affordable, and often highly sculptural objects and furnishings to many middle-class Americans.

For more than four decades, American designer Charles Eames helped shape nearly every facet of American life. From his architecture, furniture, and textile designs to his photography and corporate design, he exerted a profound influence on the visual character of daily life in America, whether at work or at home. He pioneering use of new materials and technologies, notably plywood and plastics, transformed the way Americans furnished their homes, introducing functional, affordable, and often highly sculptural objects and furnishings to many middle-class Americans.

Subscribe to:

Comments (Atom)